It is a mad rush at the moment as I try to get as much done in the Gardenqub before my vacations.

but I am pretty happy with the progress.

Take a look at how its going...

Starting to join the steel elements to the bottom elbows.

The elbow closest to the walnut tree which the client has chosen to integrate into the flooring.

It was easier than I thought to get the long elements in. This was because of the middle foot which I fixed to the element first allowing me to use it as a pivot point.

Got the bolts in but they are loose for now until we get the entire thing exactly square and in precise position.

The vertical elements are about 70kg each, but to my relieve, they slotted in perfectly. Here you can see the timber fulcrum we used to make finer adjustments in order to get the bolts in.

And here we go. The base frame is in and the uprights are in.

The base has been squared off and we leveled all the elements. We gave the entire Gardenqub about a 15mm fall to the back boundary so as to get a little natural drainage off the flooring.

Here you can see the special corner joist hanger. It is integrated into the bolt pattern of the main elbow bolts This joist will end up about 20mm away from the short frame element shown in this pic as the horizontal element. This is because of the joist shoe thickness and the bolt heads.

Now that all the proper spacers are in under the feet on the footings, the bottom frame is square and level, and all the bottom frame bolts are tight, we fill the gap between the feet and the footings with non shrink concrete grout. When that sets we'll drill a few holes down into the footings and bolt then down.

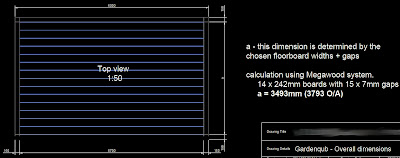

Next steps are to attach all the joist hangers to the bottom frame elements, and then install the flooring to the joists. All the floorboards are cut to the right length and the width of overall Gardenqub was adjusted so there is no board splitting.

At this point the bottom part is complete.

We are still waiting on the metal elements for the top frame which is basically a copy of the bottom frame without all the joist hanger holes.

The plan is to assemble this on the ground, and then using a small crane to lift in onto the upright elements.

Conclusion so far:

I was a little nervous as I started to assemble the parts. I had devoted a lot of time to the preparation and plans of each part of the Gardenqub so that they would slot and bolt together with the minimum of fuss and time.

As I said in a previous post, this Gardenqub, the first full size example, is much larger than what I had initially planned. So the morning of construction, a million possible things that could go wrong buzzed in my mind: could we man handle the larger elements, will everything slot in as planned, have I drilled all the holes correctly, etc....

So it was with a huge grin and a satisfied sigh of relief that I, assisted by a friend who is a office worker with basically zero experience in construction, managed to man handle and assemble the Gardenqub to this point, with hardly any swearing, no last minute cutting or bashing, in 1 day!

The only tools we used were:

At this point, I now see little to no risk for the roof element installation apart from the Cherry tree in the back left corner. We need to finesse the roof frame into the branches and then finally into the vertical elements. Considering how it has gone so far, I expect this to take a morning to complete with about 1-2 hours of crane time.

If you have been following these posts, there will be a bit of a pause now for my vacation. When I get back we will finish this project in a few quick sessions.

but I am pretty happy with the progress.

Take a look at how its going...

Starting to join the steel elements to the bottom elbows.

The elbow closest to the walnut tree which the client has chosen to integrate into the flooring.

It was easier than I thought to get the long elements in. This was because of the middle foot which I fixed to the element first allowing me to use it as a pivot point.

Got the bolts in but they are loose for now until we get the entire thing exactly square and in precise position.

The vertical elements are about 70kg each, but to my relieve, they slotted in perfectly. Here you can see the timber fulcrum we used to make finer adjustments in order to get the bolts in.

And here we go. The base frame is in and the uprights are in.

The base has been squared off and we leveled all the elements. We gave the entire Gardenqub about a 15mm fall to the back boundary so as to get a little natural drainage off the flooring.

Here you can see the special corner joist hanger. It is integrated into the bolt pattern of the main elbow bolts This joist will end up about 20mm away from the short frame element shown in this pic as the horizontal element. This is because of the joist shoe thickness and the bolt heads.

Now that all the proper spacers are in under the feet on the footings, the bottom frame is square and level, and all the bottom frame bolts are tight, we fill the gap between the feet and the footings with non shrink concrete grout. When that sets we'll drill a few holes down into the footings and bolt then down.

Next steps are to attach all the joist hangers to the bottom frame elements, and then install the flooring to the joists. All the floorboards are cut to the right length and the width of overall Gardenqub was adjusted so there is no board splitting.

At this point the bottom part is complete.

We are still waiting on the metal elements for the top frame which is basically a copy of the bottom frame without all the joist hanger holes.

The plan is to assemble this on the ground, and then using a small crane to lift in onto the upright elements.

Conclusion so far:

I was a little nervous as I started to assemble the parts. I had devoted a lot of time to the preparation and plans of each part of the Gardenqub so that they would slot and bolt together with the minimum of fuss and time.

As I said in a previous post, this Gardenqub, the first full size example, is much larger than what I had initially planned. So the morning of construction, a million possible things that could go wrong buzzed in my mind: could we man handle the larger elements, will everything slot in as planned, have I drilled all the holes correctly, etc....

So it was with a huge grin and a satisfied sigh of relief that I, assisted by a friend who is a office worker with basically zero experience in construction, managed to man handle and assemble the Gardenqub to this point, with hardly any swearing, no last minute cutting or bashing, in 1 day!

The only tools we used were:

- a few spanners

- a spirit level

- a rubber mallet to coax the steel elements into position

- some lengths of wood as levers to lift and shift the large steel elements.

- a pair of ratchet tie-down straps to bring the lower frame to square.

- a laser disto to check the diagonals before final tightening

At this point, I now see little to no risk for the roof element installation apart from the Cherry tree in the back left corner. We need to finesse the roof frame into the branches and then finally into the vertical elements. Considering how it has gone so far, I expect this to take a morning to complete with about 1-2 hours of crane time.

If you have been following these posts, there will be a bit of a pause now for my vacation. When I get back we will finish this project in a few quick sessions.